1.Stainless Steel Overview

Stainless steel is a group of iron alloys containing at least 11% chromium, an element that inhibits iron from rusting and also provides heat resistance to steel. Different types of stainless steel include carbon (from 0.03% to greater than 1.00%), nitrogen, aluminum, silicon, sulfur, titanium, nickel, copper, selenium, niobium, and molybdenum. Specific types of stainless steel are often referred to by their AISI three-digit number, such as 304 stainless steel.

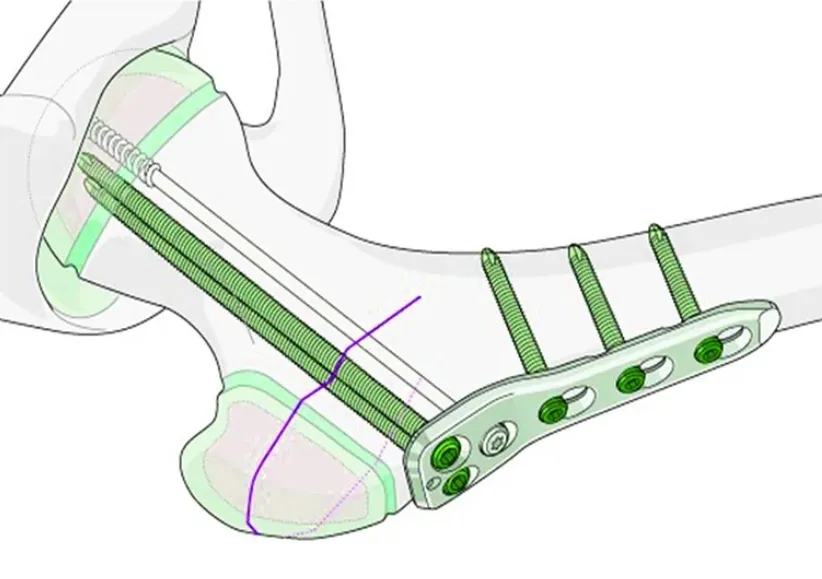

Stainless steel can be rolled into sheets, plates, bars, wires and tubes. Stainless steel is an ideal material for many applications as it has the strength of steel and the corrosion resistance of chromium. It is used in many applications such as cookware, cutlery, surgical instruments (medical bone plates), major appliances, vehicles, construction materials in large buildings, industry and storage tanks and tank cars for chemicals and food.

2.Stainless steel classification

Stainless steels are generally divided into four different groups:

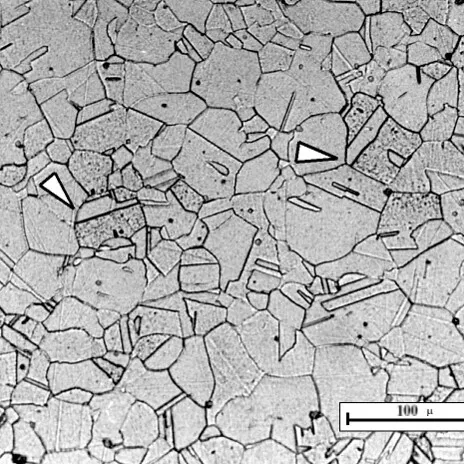

Austenitic Stainless Steel: This is the most common type of stainless steel. Austenitic stainless steel has higher levels of chromium, molybdenum, and nickel than other types of stainless steel. It is highly adaptable and known for its excellent strength and ductility.

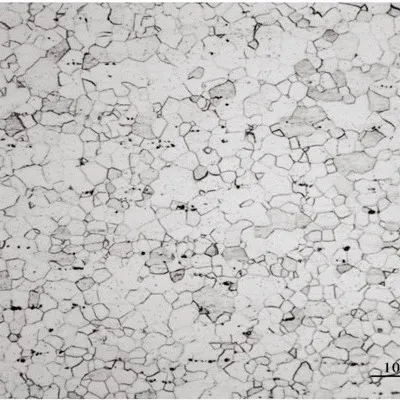

Ferritic stainless steel

Ferritic stainless steel: This steel contains between 10.5% and 30% chromium. Ferritic stainless steels typically have low carbon contents of no more than 0.1%. Ferritic stainless steels are magnetic and are primarily preferred for their resistance to temperature, corrosion, and stress-deterioration cracking.

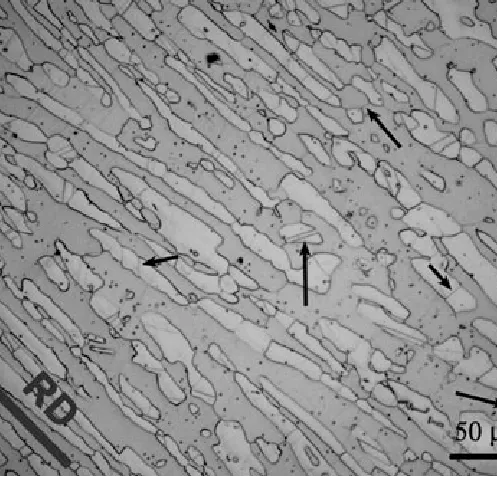

Duplex stainless steel

Duplex Stainless Steel: This steel combines austenite and ferrite to create a metal that is stronger than either alone. This combination gives the steel greater strength, which can result in significant weight savings. Its corrosion resistance makes it ideal for use in marine applications.

Martensitic stainless steel

Martensitic stainless steel: This steel is similar in structure to ferritic stainless steel, but has a higher carbon content (up to 1.2%), which allows the steel to be hardened to a great extent. This steel is particularly useful in making medical tools and surgical instruments.

3.Stainless steel components

1.Stainless steel 203S Iron (67.775 – 71.775%), chromium (17 – 19%), nickel (8 – 10%), manganese (2%), silicon (1%), carbon (0.15%), sulfur (0.03%), phosphorus (0.045%)

2.Stainless steel 301 Iron (70.675 – 74.675%), carbon (0.15%), manganese (2%), phosphorus (0.045%), sulfur (0.030%), silicon (1%), chromium (16 – 18%), nickel (6 – 8%), nitrogen (0.10%)

3.Stainless steel 304 Iron (66.74 – 74.5%), carbon (0.07%), manganese (2.0%), silicon (1.00%), phosphorus (0.05%), sulfur (0.03%), chromium (17.50 – 19.50%), Nickel (8.0 – 10.50%), Nitrogen (0.11)

4.Stainless steel 304L Iron (66.69 – 74.0%), Carbon (0.03%), Manganese (2.0%), Silicon (1.00%), Phosphorus (0.05%), Sulfur (0.02%), Chromium (17.50 – 19.50%), Nickel (8.0 – 10.50%), Nitrogen (0.11)

5.Stainless steel 303S Iron (67.44 – 71.44%), Chromium (17 – 19%), Nickel (8 – 10%), Manganese (2%), Silicon (1%), Phosphorus (0.2%), Carbon (0.15%), Selenium (0.15%), Sulfur (0.06%)

6.Stainless steel 303Se Iron (67.44 – 71.44%), Chromium (17 – 19%), Nickel (8 – 10%), Manganese (2%), Silicon (1%), Phosphorus (0.2%), Carbon (0.15%), Selenium (0.15%), Sulfur (0.06%)

7. Stainless steel 316 Iron (61.995 – 69.095%), Carbon (0.08%), Manganese (2.0%), Silicon (0.75%), Phosphorus (0.045%), Sulfur (0.03%), Chromium (16 – 18%), Molybdenum (2.0 – 3.0%), Nickel (10 – 14%), Nitrogen (0.10%)

8.Stainless steel 316L Iron (62.045 – 69.145%), Carbon (0.05%), Manganese (2.0%), Silicon (0.75%), Phosphorus (0.045%), Sulfur (0.03%), Chromium (16 – 18%), Molybdenum (2.0 – 3.0%), Nickel (10 – 14%), Nitrogen (0.10%)

9.Stainless steel 321 Iron (65.295 – 70.375 %), Carbon (0.08%), Manganese (2.0%), Silicon (0.75%), Phosphorus (0.045%), Sulfur (0.03%), Chromium (17 – 19%), Nickel (9.0 – 12.0%), Nitrogen (0.10%), Ti=5(C+N 0.70%)

10.Stainless steel 347 Iron (64.995 – 69.075 %), Carbon (0.08%), Manganese (2.0%), Silicon (0.75%), Phosphorus (0.045%), Sulfur (0.03%), Chromium (17 – 19%), Nickel (9.0 – 12.0%), Nitrogen (0.10%), Nb=10(C+N 1.0%)

11.Stainless steel 410 Iron (83.53 – 85.53%), Carbon (0.15%), Manganese (1.0%), Silicon (1.0%), Phosphorus (0.04%), Sulfur (0.03%) Chromium (11.5 – 13.5%), Nickel (0.75%)

12.Stainless steel 416 Iron (82.79 – 87.85%), Carbon (0.15%), Mn (1.25%), S Silicon (1.0%), Phosphorus ( 0.06%), Sulfur (0.15 %), Chromium (12 -14%), Mo (0 – 0.6%)

13 Stainless steel 418 Iron (82%), Cr (13%), W (3%), Nickel (2%)

14. Stainless steel 431 Iron (78.23 – 83.75%), Carbon (0.20%), Mn (1%), Silicon (1%), Phosphorus (0.04%), Sulfur (0.03%), Cr (15 – 17%), Nickel (1.25 – 2.50%)

15 .Stainless steel 440C Iron (79.15%), Cr (17%), Carbon (1.1%), Mn (1%), Silicon (1%), Molybdenum (0.75%)

16 .Stainless steel 13-8 PH VAR Iron (74.122 – 77.35%), Carbon (0.05%), Mn (0.10%), Silicon (0.10%), Phosphorus (0.010%), Cr (12.25 – 13.25%), Nickel (7.5 – 8.5%), Molybdenum (2.00 – 2.50%), Nitrogen (0.010%), Aluminum (0.90 – 1.35%)

17. Stainless Steel 15-5 PH VAR Iron (71.91 – 77.71%), Carbon (0.07%), Manganese (1.0%), Sulfur (0.040%), Sulfur (0.03%), Silicon (1.0%), Chromium (14.0 – 15.50%), Nickel (3.50 – 5.50%), Cu (2.50 – 4.50%), Nb+Ta (0.15 – 0.45%)

18.Stainless steel 17-4 PH Iron (73%), Cr (15.0 – 17.5%), Nickel (3.0 – 5.0%), Cu (3.0 – 5.0%), Manganese (1.0%), Silicon (1.0%), Ta (0.45%), Nb/Cb (0.45%), Nb + Ta (0.15 – 0.45%), Carbon (0.070%), Phosphorus (0.040%), Sulfur (0.030%)

Post time: Sep-27-2024